Understanding Health and Safety: Practices, Standards, and Technology

Introduction:

The history of workplace health and safety is a journey of continuous improvement. From the hazardous environments of the Industrial Revolution to today’s regulated, safer workplaces, the evolution of safety standards like OHSAS 18001 and ISO 45001 reflects the growing importance of occupational health and safety (OHS). Modern health and safety management systems are integral to reducing workplace accidents and ensuring a safe working environment for all employees.

Early Workplace Conditions

In the early days of industrialization, workplace safety was hardly a consideration. Factories were dangerous places where workers faced numerous risks with little protection. The absence of structured health and safety management systems meant that accidents were frequent, often resulting in severe injuries or fatalities. As a result, the need for a systematic approach to managing occupational health and safety became increasingly apparent.

The Industrial Revolution and Its Impact

The Industrial Revolution marked a significant turning point in workplace safety. As industries grew, so did the incidence of workplace accidents. Workers were exposed to unsafe machinery, hazardous substances like asbestos, and grueling working hours. Without safety regulations, injuries and deaths were common. This period highlighted the urgent need for systematic safety measures, laying the groundwork for modern occupational health and safety practices. The era also saw the beginning of health and safety audits, which would later evolve into comprehensive safety management systems.

The Birth of Labor Unions and Early Safety Laws

The dangerous working conditions of the Industrial Revolution led to the rise of labor unions, which played a crucial role in advocating for safer work environments. These unions were instrumental in pushing for early safety laws that began to address some of the most severe workplace hazards. These initial laws, though basic, set the stage for more comprehensive safety standards, including the development of occupational health and safety frameworks like OHSAS 18001.

The Development of Modern Safety Standards

As societies industrialized further, the approach to workplace safety became more structured. The 20th century saw the formalization of occupational health and safety as a recognized field, with governments and organizations acknowledging the critical importance of protecting workers’ health. This era brought significant legislative advancements and the development of international safety standards that continue to shape workplace safety today.

The Rise of Occupational Health as a Field

Occupational health became a recognized field in the early 20th century, focusing on preventing work-related injuries and illnesses. The establishment of dedicated institutions and training programs for professionals in workplace health and safety marked a significant shift towards more scientific and systematic approaches to managing risks. This period saw the introduction of safety management systems that later evolved into standards like ISO 45001, designed to help organizations proactively manage health and safety risks.

Key Legislation Shaping Health and Safety

Several key pieces of legislation have been instrumental in shaping the landscape of workplace health and safety. In the United States, the Occupational Safety and Health Act (OSHA) of 1970 established national standards for workplace safety. This groundbreaking law, along with similar regulations worldwide, provided a legal framework for enforcing health and safety measures, leading to the widespread adoption of standards like OHSAS 18001 and ISO 45001. These regulations have played a vital role in reducing workplace accidents and improving overall safety conditions.

Significant Events and Their Influence on Safety Practices

Throughout history, significant industrial accidents have prompted major changes in safety practices. These events often serve as catalysts for reform, leading to the implementation of stricter regulations and improved safety measures across industries.

Major Industrial Accidents and Their Aftermath

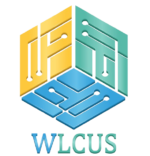

Bhopal Gas Tragedy 1984

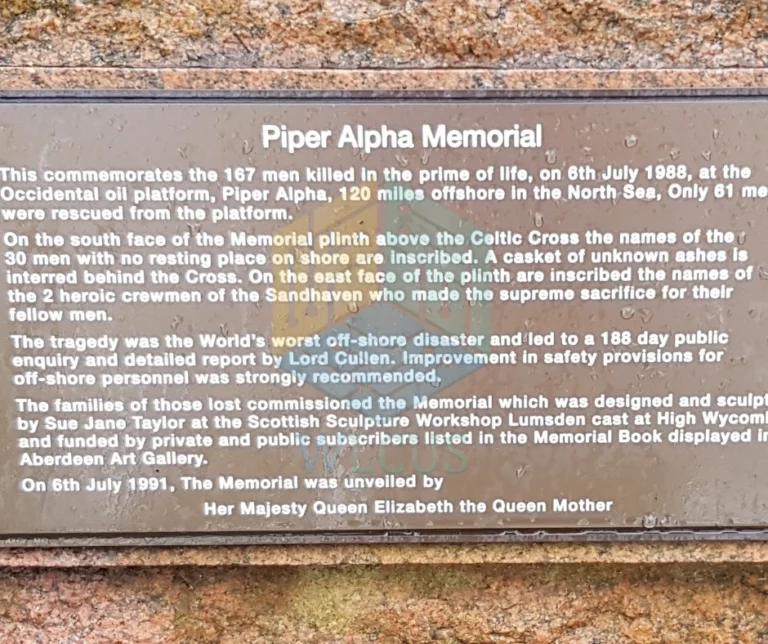

Piper Alpha Oil Rig Disaster 1988

Texas City Refinery Explosion 2005

Deepwater Horizon Oil Spill 2010

Rana Plaza Collapse 2013

Bhopal Gas Tragedy (1984) – The Aftermath Continues

Incident Overview:

On the night of December 2-3, 1984, a gas leak occurred at the Union Carbide India Limited (UCIL) pesticide plant in Bhopal, India. Methyl isocyanate (MIC) gas, a highly toxic substance, was accidentally released, exposing over 500,000 people to the poisonous fumes.

Casualties:

The immediate death toll was estimated at around 3,000 people, but the long-term effects brought the total number of deaths to between 15,000 and 20,000. Over 500,000 people suffered injuries, with many experiencing chronic respiratory and vision problems.

Impact on Health and Safety:

The Bhopal disaster is considered one of the world’s worst industrial accidents and had a significant influence on global health and safety regulations. It highlighted the need for stricter controls in chemical plants and led to the development of new safety protocols, particularly in handling toxic substances. In India, the disaster led to the passage of the Environment Protection Act in 1986, which aimed to prevent future industrial disasters.

Long-term Effects:

The aftermath of the Bhopal disaster continues to be felt today. The site remains contaminated, and many survivors still suffer from health complications. The incident led to international safety regulations, particularly in chemical industries, emphasizing the need for robust health and safety management systems.

Piper Alpha Oil Rig Disaster (1988) – Regulatory Reforms in the 1990s

Incident Overview:

On July 6, 1988, an explosion occurred on the Piper Alpha oil platform in the North Sea, approximately 120 miles northeast of Aberdeen, Scotland. The explosion was caused by a gas leak from a corroded pipe, which ignited and led to a series of devastating fires.

Casualties:

The disaster claimed the lives of 167 out of 226 crew members. It remains the deadliest offshore oil disaster in history.

Impact on Health and Safety:

The Piper Alpha disaster had a profound impact on offshore safety regulations. The Cullen Inquiry, which investigated the disaster, resulted in 106 recommendations for improving safety in the oil and gas industry. One of the most significant outcomes was the introduction of the Safety Case Regulations in 1992. These regulations required companies to demonstrate the safety of their operations, particularly in high-risk industries like oil and gas. The disaster also led to a shift in the regulatory regime, with greater emphasis on risk assessment and management.

Long-term Effects:

The lessons learned from Piper Alpha have been incorporated into safety practices worldwide. The incident underscored the importance of safety culture, risk management, and emergency preparedness, leading to stricter regulations and improved safety protocols in the oil and gas industry.

Texas City Refinery Explosion (2005) – Focus on Corporate Accountability

Incident Overview:

On March 23, 2005, a massive explosion occurred at the BP refinery in Texas City, Texas. The explosion was triggered by the overfilling of a hydrocarbon isomerization unit, which caused a vapor cloud to ignite.

Casualties:

The explosion killed 15 workers and injured more than 180 others. It also caused significant damage to the refinery and surrounding areas.

Impact on Health and Safety:

The Texas City explosion highlighted serious deficiencies in BP’s safety management and corporate accountability. The incident led to significant legal repercussions for BP, including fines and lawsuits. In response, BP implemented widespread safety reforms and made a public commitment to improving its safety culture. The disaster also prompted the U.S. Chemical Safety Board (CSB) to issue recommendations for improving safety management systems across the industry.

Long-term Effects:

The Texas City explosion served as a wake-up call for the oil and gas industry, emphasizing the importance of corporate responsibility in maintaining safety standards. It led to a reevaluation of safety protocols and greater scrutiny of safety practices within the industry. The incident also reinforced the need for robust health and safety management systems like ISO 45001.

Deepwater Horizon Oil Spill (2010) – Environmental and Safety Implications

Incident Overview:

On April 20, 2010, the Deepwater Horizon oil rig, operated by BP, experienced a blowout while drilling in the Macondo Prospect in the Gulf of Mexico. The blowout caused a massive explosion, followed by a fire that sank the rig two days later.

Casualties:

The explosion killed 11 workers and resulted in the largest marine oil spill in history, with approximately 4.9 million barrels of oil discharged into the Gulf of Mexico over 87 days.

Impact on Health and Safety:

The Deepwater Horizon disaster exposed significant flaws in safety procedures within the oil industry, particularly in deepwater drilling. The incident led to stricter offshore drilling regulations, including the implementation of new safety and environmental standards by the U.S. government. The Bureau of Safety and Environmental Enforcement (BSEE) was established to oversee offshore drilling operations and enforce these regulations.

Long-term Effects:

The disaster prompted a broader discussion on sustainable industrial practices and the need for improved safety protocols in high-risk industries. It also led to significant financial and reputational damage for BP, which faced billions of dollars in fines and settlements. The Deepwater Horizon incident highlighted the need for continuous improvement in safety management systems and reinforced the importance of environmental stewardship.

Rana Plaza Collapse (2013) – A Turning Point for Global Supply Chain Safety

Incident Overview:

On April 24, 2013, the Rana Plaza building, which housed several garment factories, collapsed in Dhaka, Bangladesh. The building had been constructed with substandard materials and did not comply with safety regulations.

Casualties:

The collapse killed 1,134 workers and injured more than 2,500 others, making it one of the deadliest industrial disasters in history.

Impact on Health and Safety:

The Rana Plaza disaster exposed severe safety violations and poor working conditions in global supply chains, particularly in the garment industry. In response, international brands and labor unions came together to create the Bangladesh Accord on Fire and Building Safety. This legally binding agreement set new standards for building safety and workers’ rights in Bangladesh, including regular inspections and mandatory repairs for factories.

Long-term Effects:

The Rana Plaza collapse marked a turning point for global supply chain safety. It led to increased awareness of the importance of workplace safety in developing countries and prompted reforms in the global garment industry. The incident also underscored the need for multinational companies to take responsibility for the safety and well-being of workers in their supply chains.

The Role of Technology in Workplace Safety

Technology has played a transformative role in enhancing workplace safety. Innovations such as Machine Learning (ML), Artificial Intelligence (ai) and IoT (Internet of Things), and wearable devices have enabled real-time monitoring of workplace conditions, predicting potential hazards before they occur. These advancements have significantly contributed to reducing accidents and improving overall safety.

The Future of Occupational Health and Safety

Technology has played a transformative role in enhancing workplace safety. Innovations such as Machine Learning (ML), Artificial Intelligence (ai) and IoT (Internet of Things), and wearable devices have enabled real-time monitoring of workplace conditions, predicting potential hazards before they occur. These advancements have significantly contributed to reducing accidents and improving overall safety.

Conclusion

In summary, the evolution of workplace health and safety practices, from the rudimentary measures of the Industrial Revolution to the sophisticated standards of today, clearly reflects society’s growing commitment to protecting workers. Moreover, the integration of technology, the establishment of comprehensive safety management systems, and the lessons learned from past industrial disasters all significantly contribute to a safer and healthier working environment. As we look to the future, the continued emphasis on occupational health and safety will undoubtedly be essential in creating workplaces where everyone can thrive.